Description

CHUBB DEMOUNTABLE EXTENDABLE VAULT

The Chubb Demountable Extendable Vault (DEV) provides banks and other organisations handling large amounts of cash or other valuables, with a high security strongroom which can be adapted to changing security arrangements.

The DEV is constructed from modular prefabricated panels which can easily be installed in existing premises. It provides great flexibility as additional panels can be supplied to extend the vault or it can be completely dismantled and relocated which is particularly suitable for leased premises.

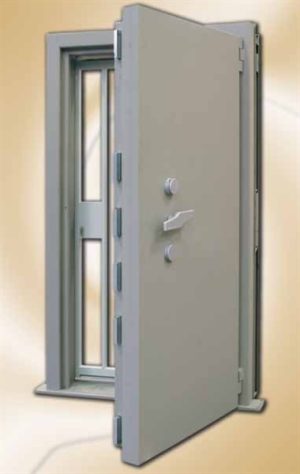

DOORS

MAIN DOORS – The DEV is supplied with a high security Chubb Vault Door which can be placed in either the end or the side of the vault. There is a choice of the following types of door:

- Torch and Drill Resisting Door: These doors resist attacks with oxy-acetylene, drills, diamond core drills, explosives, impact and cutting tools and a combination of these attacks. They are available with a total barrier thickness of 3 1/2″ or 5″.

- Anti Arc Door: The 3 1/2″ Anti Arc door provides all the protection of a 3 1/2″ TDR door but with added protection against an oxy-arc cutting tool. This form of attack combines oxygen cutting with the extra power of an electric arc.

- Anti Lance Doors: The thermic lance generates temperatures of up to 4,500°C capable of burning through most materials. Our specially developed anti lance material provides protection from this form of attack and is used with other materials to give a total barrier thickness of 5″. These doors are fitted with dual key or combination locks.

- Emergency Door: This door has all the security features of a main door and provides access into the Vault if the main door cannot be opened, possibly as a result of an attack. If staff are to work in the Vault or customers have access to safe deposit lockers in the Vault, forced ventilation can be provided through the Emergency door. This also ensures that the operation of the door is regularly checked. An Emergency door can be provided in any standard extension panel, except those immediately adjacent to the main door panels.

VENTILATION

The provision of an efficient ventilation system is imperative in tropical climates or where staff and the general public may be working inside the vault. Installing air conditioning trunking through the vault structure creates an unacceptable security hazard and the most effective method of supplying air to the vault is through the emergency door aperture which may be fitted with a ventilation plenum device for this purpose. During times of maximum security, the emergency strongroom door seals the aperture, but during working hours this door is swung-open and the ventilation plenum closed. This system has the added advantage that the locking mechanism on the emergency door is checked each working day.

CONSTRUCTION

The panels are protected by a special highly reinforced barrier material which is securely anchored to an inner steel plate. The barrier resists attacks with thermal tools including oxy acetylene, arc-air and oxy arc. It contains a high concentration of very hard abrasion resistant material which blunts drills and wears out discs. These panels, which include integral corner sections, bolt together securely from the inside providing protection against forcing, ramming and explosives attacks. These features combine to provide protection against all practical forms of attack by burglars.

ROOF

Roof panels, of the same construction as the walls, are supplied as standard.

FLOOR

For all round balanced security, floor panels of exactly the same construction are recommended. An alternative steel plate floor is however, also available. This plate floor is suitable for applications in which the DEV is built onto a foundation reinforced with special Chubb Spiral or Tangbar burglar resisting steel reinforcement. Both types of floor panel can be prepared for secure anchoring to the building, although the DEV is heavy enough in itself not to require this, in most applications.

BURGLAR RESISTANCE TESTS

All Chubb designs are thoroughly tested to destruction at our Wolverhampton factory. The standard DEV has panels 160mm (6.3″) thick and these have been independently assessed by Underwriters Laboratory in the USA as providing Class 2 burglary resistance certificate number BP3929(N). A special extra thick version of the panels is available to meet the Swedish SMS 3000 burglar resistance standard. These 240mm (9.45″) thick panels achieved a very high rating of 1440 to 1660 points.

The Chubb DEV is manufactured and inspected under procedures approved by British Standards Institution. Chubb Safe Equipment Company is the first vault and safe manufacturer registered under BS5750. The initial assessment is followed by regular unannounced surveillance visits normally four times a year, but at the discretion of BSI, to ensure that standards are maintained.

FINISH

The inside of the DEV is painted grey and the outside surface can be finished with plaster or with a masonry paint applied with a brush or roller after installation. The outside of the panels can be clad in steel sheet at extra cost.

LIGHTING

A panel can be prepared to take wiring into the vault. However, to eliminate any possibility of a short circuit causing a fire inside a closed vault, the main door can be fitted with a microswitch to automatically disconnect the power when it is closed.

COMPREHENSIVERANGE OF SIZES

The DEV is available in a comprehensive range of sizes and as long as required, with main door in a choice of positions.

INTERNAL FITTINGS

We offer a comprehensive range of steel security cupboards and safe deposit lockers available upon request.